What the future is made of

Our engineered materials-focused products and services enable real mass production with additive manufacturing (AM) – now.

Materials are at the heart of all manufacturing processes, but AM is a disruptive new technology that requires special materials for peak performance and volume production.

“…current methods for producing metal powders – traditional gas atomization processes – inherently produce unwanted characteristics in final manufactured parts.” – Wohlers Associates

To provide powder specifically designed for AM, Equispheres has developed an innovative, proprietary technology that enables precise manipulation of powder characteristics.

This technology allows our powder design engineers to modify, shape, and adjust critical powder attributes, including shape, size, sphericity, and oxygen content.

The result is engineered powder optimized for AM applications that enables safe and economic volume production.

Non-explosible powder

Using our proprietary technology, Equispheres has designed the world’s first and only non-explosive aluminum powder.

Standard aluminum powder is inherently explosive. Although this is a good attribute for pyrotechnic and rocket propulsion applications, it is a significant safety risk in manufacturing applications. Volume use of aluminum for production requires specialized handling and considerable safety infrastructure and handling, including expensive explosion-proof storage facilities.

By careful manipulation of key powder attributes, Equispheres has engineered our NExP-1 aluminum powder so that it does not compromise on build speed or part quality but is dust free and non-explosible per ASTM E1226, Standard Test Method for Explosibility of Dust Clouds.

Equispheres designed this powder to remove an impediment to volume AM production – and because we can.

Learn more about our non-explosible NExP-1 Powder >

Production speeds (make the most of your printers)

Equispheres powder has been engineered to print rapidly and to significantly reduce the cost of production. Because the powder packs densely and lays in a uniform grade, it absorbs the laser energy evenly and efficiently. This enables operators to spread thicker powder layers, which increases the vertical build speed and allows increased scan speed and hatch distances that improve the horizontal print speeds. These are multiplicative factors that improve build rates by a factor of 2 to 4.

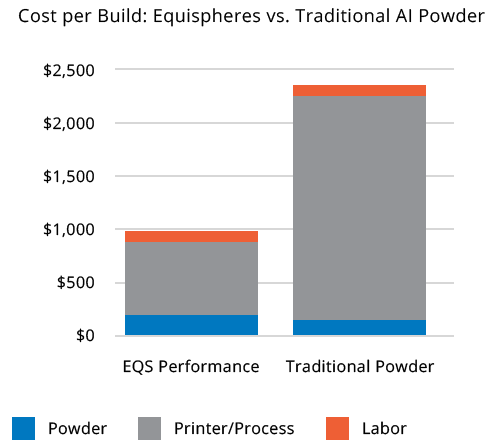

AM printers are expensive devices, and the expense of the machine must be amortized across the volume of parts produced. Because printers produce parts slowly, the print process constitutes most of the cost in part production. Therefore, increasing the speed of production by 4 times can achieve a dramatic 50% cost savings in part production.