By substantially reducing production time, high-performance print material can reduce production cost by ~50% and enable metal AM to compete more effectively with casting processes.

Background

When making production choices, automakers are laser-focused on part cost. A major obstacle to the adoption of metal additive manufacturing for automotive parts is the cost of production.

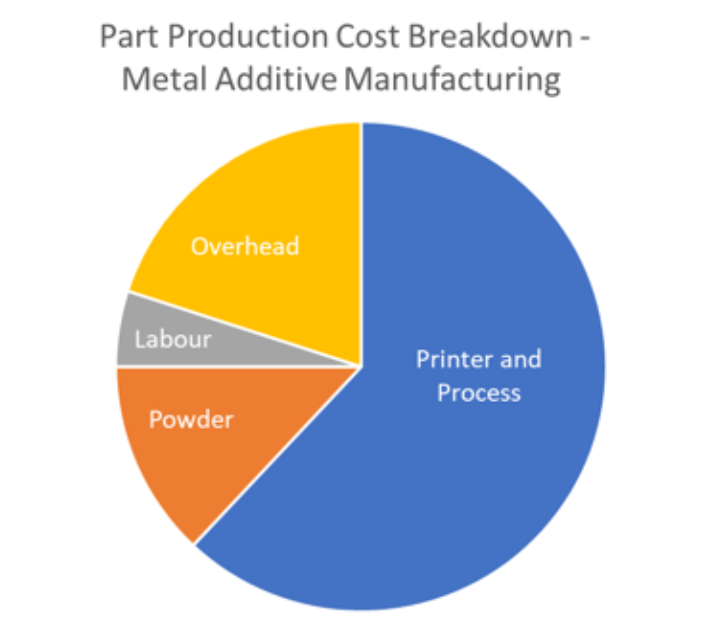

Metal additive manufacturing (sometimes called metal AM) printers are understandably expensive, but they are also very slow compared to traditional manufacturing methods used in automotive. As shown, most of the cost to produce a part is associated with the printer as the expense of purchasing, operating, and maintaining the machine must be amortized over the number of parts produced by the device.

Metal additive manufacturing (sometimes called metal AM) printers are understandably expensive, but they are also very slow compared to traditional manufacturing methods used in automotive. As shown, most of the cost to produce a part is associated with the printer as the expense of purchasing, operating, and maintaining the machine must be amortized over the number of parts produced by the device.

Metal AM involves laying down a thin layer of powder and (typically) using a laser to micro-weld the particles together. The laser “scans” (moves) horizontally across the powder bed to melt the powder in the areas defining the part shape. When this is completed, another powder layer is deposited and the process repeats. With each new powder layer, the part is built upward vertically.

Despite the recent advances in printer technology, with many manufacturers offering machines with multiple high powered lasers, the process is still limited (especially for aluminum) by the poor quality of traditional powder feedstock. When working with a poor-performing material, the laser must scan more slowly to achieve quality print results. Furthermore, poor quality powder does not pack densely, and the powder must be laid down in very thin layers to ensure it is properly melted, which reduces the vertical build rate.

Equispheres has been working with automakers to optimize the part production process, based on the capabilities of our high-quality powder. With better quality powder, manufacturers can improve the horizontal scan rate and employ thicker powder layers to increase the speed of part production and thereby reduce part costs.

In the automotive world, speed isn’t only important on the track. Speed also matters on the factory floor because of the intense cost pressures in this industry. Using Equispheres’ powder, two automakers have achieved significant increases in the production speed of aluminum parts made by additive manufacturing.

Summary of Key Results

Vertical Build Speed

Equispheres has been working in collaboration with an automaker using AM as a growing part of its prototyping and production.

Typically, this automaker prints parts using a 30 um powder thickness layer. In consultation with the Equispheres Applications Engineering group, printer parameters for thicker powder layers (i.e., 90 um) were developed to enable speed improvements while maintaining mechanical performance.

By utilizing the 90 um powder layers, the customer achieved a 3 times increase in production speed with an improvement in mechanical properties. Test specimens exhibited mechanical properties surpassing the company’s benchmark powder material by ~10% on key performance criteria.

| Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | |

|---|---|---|---|

| Equispheres powder | 236.00 | 384.00 | 4.30 |

| Benchmark powder | 220.00 | 323.00 | 2.60 |

| Improvement | 7.27% | 18.89% | 65.38% |

Horizontal Build Speed

Equispheres has been working with a global producer of consumer cars that has embraced additive manufacturing and currently produces a limited number of parts using 3D printing.

Typically, this automaker produces parts at a build rate of 50 cm3 per hour. It has been demonstrated that the high quality of Equispheres’ powder permits more efficient absorption of laser energy. This characteristic allowed the customer to increase the scan speed and hatch distance (i.e., the space between micro welding beads) to improve the horizontal speed of production. As shown below, the build rate was increased to 84 cm3 per hour (~68% increase) without any negative impact to strength.

Why it Matters

Improvements to build speed in the horizontal and vertical directions are complementary. Therefore, by combining the benefits of increased laser speed and increased layer thickness, users of Equispheres’ powders can achieve a 4 times increase in build rate and 3 times reduction in overall production time. By substantially reducing the production time, Equispheres’ powder can reduce production cost by ~50%, as shown above, and enables metal AM to compete more effectively with casting processes.