We are known for our high-performance metal powders, but first and foremost Equispheres is a materials science engineering firm. Our deep knowledge of metallurgy and metal technology is what allows us to produce powders with the performance and properties we do. By sharing our research, insights and white papers we hope to help the entire industry advance faster and achieve more, sooner. Browse all available videos, papers and reports below or contact us for any specific queries or to talk to one of our Materials Science Experts.

Videos

Trends in Metal Additive Manufacturing: The Importance of Powder

What do end-users want? A panel of experts, including a materials specialist from Divergent 3D, discusses what the automotive sector needs from metal AM and which powder characteristics can contribute to higher productivity and lower costs.

Webinar: Improving Performance and Quality in Aluminum Additive Manufacturing

Learn how to improve Aluminum L-PBF productivity by leveraging Equispheres’ unique powder attributes. Topics include: process stability, boosting productivity without sacrificing quality, and achievable print speeds.

Webinar: Accelerating Metal Additive Manufacturing – the Importance of Powder / Printer Combination

Equispheres and Aconity3D discuss ways to significantly increase the speed of part production and dramatically reduce costs using modern, high-precision powder-bed fusion printers combined with powder optimized for AM.

DOWNLOADS

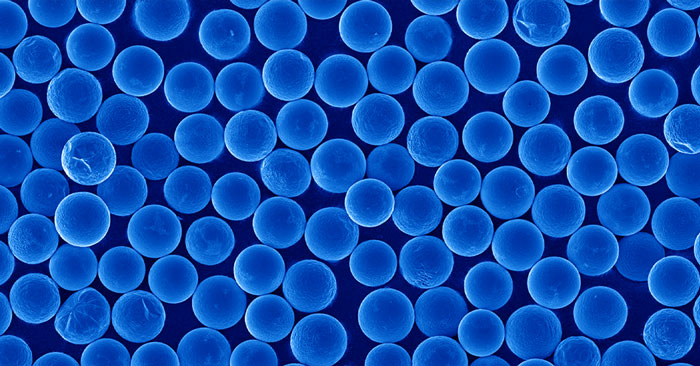

Understanding the Factors Influencing Powder Spreadability For Laser Powder Bed Fusion

Powder flow behaviour is an important aspect of the build process. How can we achieve good spreadability to create consistent powder layering and, ultimately, high-quality parts?

High-Performance Aluminum Powder: Fueling Metal AM Market Growth

Learn how our innovative, high performance aluminum powder is pushing the metal additive manufacturing market forward.

Impact of Powder Size, Size Distribution and Morphology on Additive Manufacturing

What’s the secret to consistent parts? Dr. Conlon explains how various powder characteristics affect key mechanical properties in the final product—dimensional accuracy, hardness, surface roughness, tensile strength, yield strength, and density.