Powder attributes:

Equispheres’ breakthrough powder production technology was engineered for the AM industry to produce powder with ideal properties for additive manufacturing. These include uniform size, sphericity, and consistent microstructure — as well as smoother surface and thinner oxide layer — resulting in more rapidly manufactured metal parts with superior mechanical properties.

Not all powders are created equal – ours are.

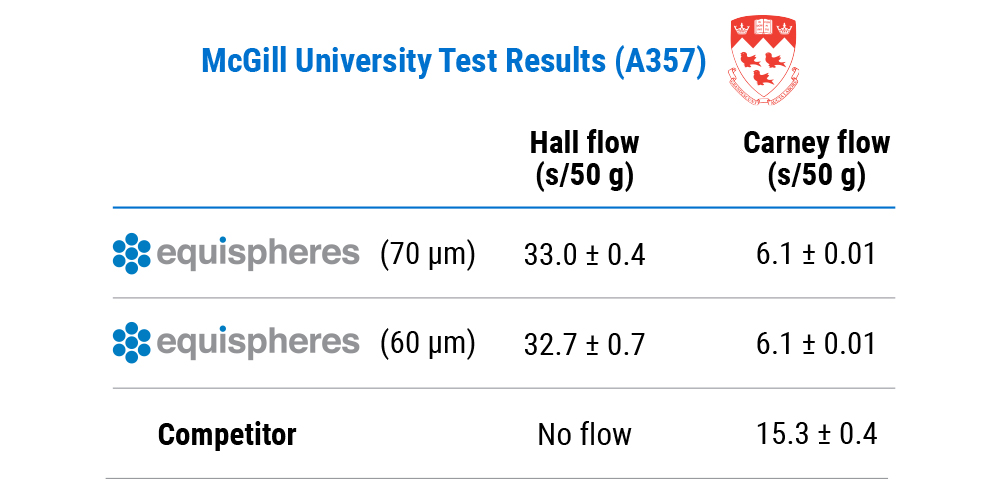

Superior flowability and spreadability

In powder bed additive manufacturing, round and smooth particles move more freely than the irregular shaped particles with unwanted microscopic fines (ø: 0.1–5µm) found in standard atomized powder that tend to clump and prevent uniform layer deposition. Equispheres’ powder is spherical, agglomerate- and fine-free, and rolls smoothly under the powder bed blade/roller for greatly improved spreadability. The result: a final product with superior surface finish and better mechanical properties.

The minimal fines in our powders significantly increase flowability. Recent testing conducted by McGill University identified that Equispheres’ powder flows 2.5 times faster than competitive powders (using standard flow test techniques).

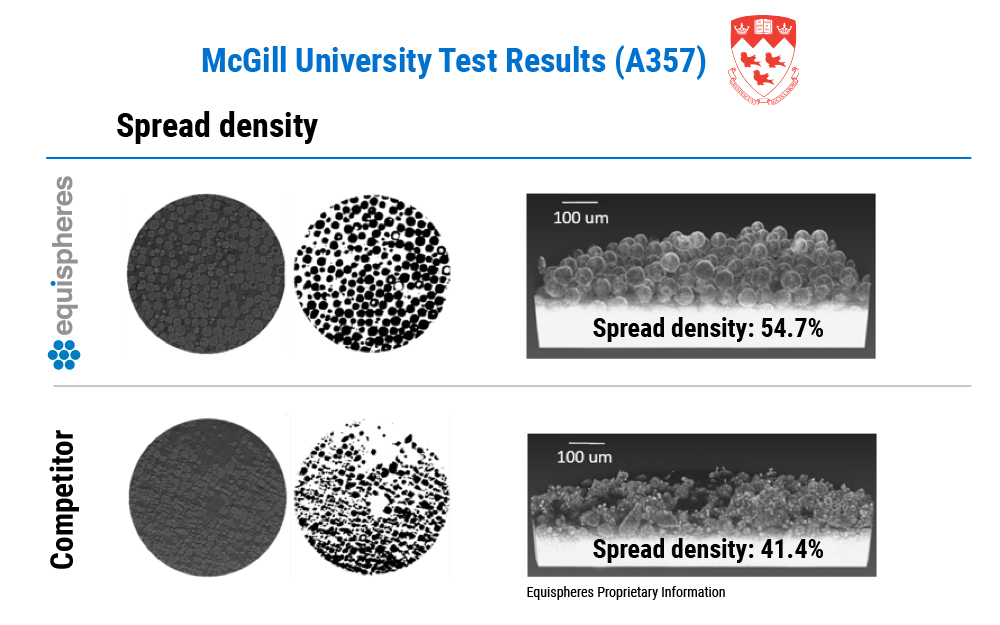

Greater packing density and spread density

Irregular particles and “fines” interfere with packing density. Equispheres’ powders pack much more densely and uniformly than those of competitors. Because Equispheres’ powder is highly flowable, achieved density in “real-world” powder bed (i.e. spread density) is virtually identical to “tap” density achieved in the laboratory and 30% better than competitive powders. This allows the production of denser parts with smoother as-built surfaces.

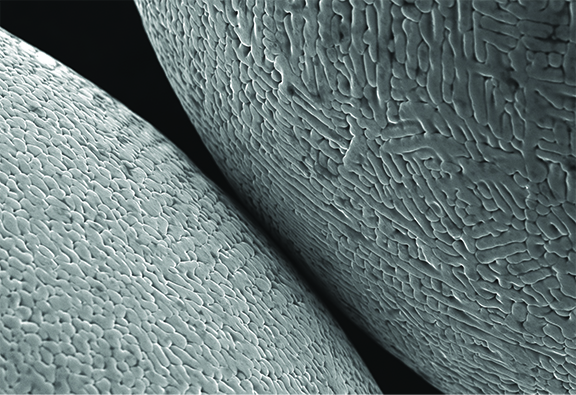

Thin oxide layers with less water adsorption

A common problem with metal powders has been the thickness of the oxide layer. While a thicker oxide layer results in poor mechanical properties in the final manufactured part, a powder with thinner oxide layers tends to adsorb water, which also has a negative impact on part performance.

However, Equispheres’ powders have both a thin oxide layer and low water adsorption — a direct result of the superior morphology of our powder.

Independent lab testing by McGill University has shown that Equispheres’ powders have an oxide layer half as thick as its competitors, but with one-third the water adsorption.

The result is less powder preparation prior to printing and superior product performance.

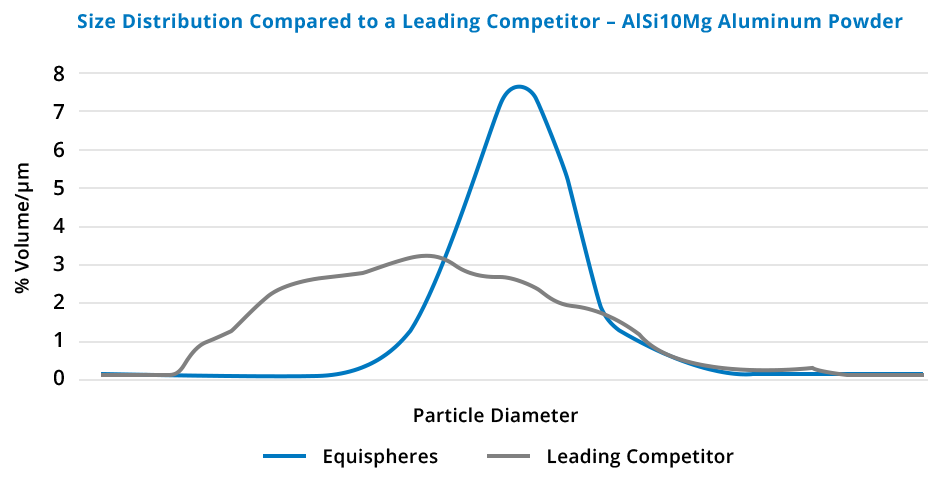

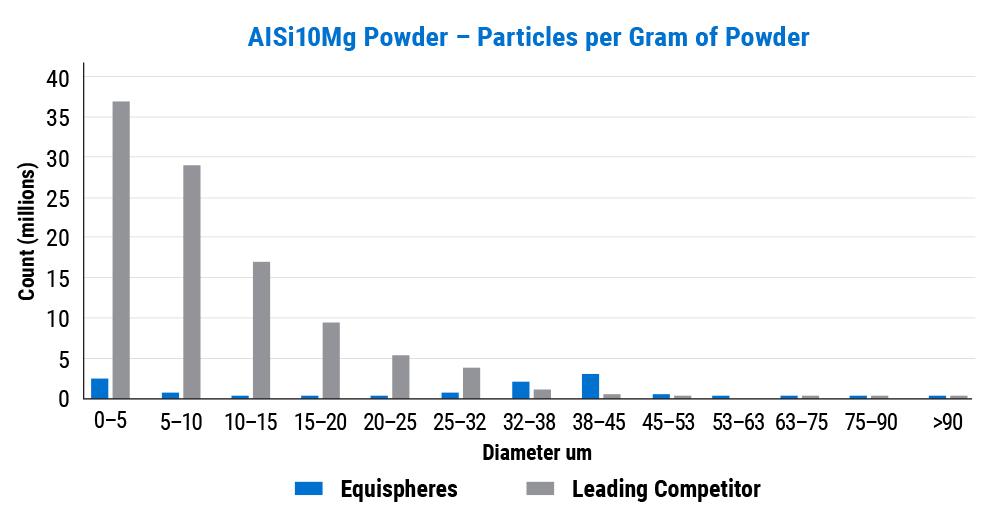

More uniform melt and solidification in every layer

Equispheres’ novel process is highly controlled and generates a very fine microstructure, with uniform particle sizes. Competing powders include particles of various sizes. When their powders are melted by the laser used in additive manufacturing, the smaller particles cool faster than the larger ones, producing an inconsistent microstructure.

Equispheres’ powder melts and solidifies uniformly and predictably. The result is a final product produced rapidly with consistent and superior mechanical properties.

Safety

Fine metal powder particles are more than just a nuisance in the manufacturing process — they can be dangerously explosive. Equispheres’ powders have a minimal quantity of fines and are therefore much safer to handle. This can simplify the complexity and reduce the costs of safety equipment normally required when dealing with certain metal powder alloys.

Take advantage of our powder

Looking for more stats? Download an overview of Performance Data for AlSi10Mg to get additional technical detail.

Ready to give our powder a try? Work closely with Applications Engineering support services to quickly transition from your current materials and fully benefit from the lower costs and superior performance our powder can offer. We offer starter program packages to expedite the process of powder qualification and process optimization for your unique performance and production requirements.