In laser powder bed fusion (L-PBF), key process variables and process control play an outsized role in determining final part material properties because the raw material is undergoing a transformation as the part is being built. Collaboration and information sharing among materials suppliers and the design/manufacturing teams are critical to ensuring high-quality parts are produced as efficiently as possible.

Engineers, designers and executives accustomed to more traditional manufacturing methods may be surprised to learn how much influence material selection and key process variables can have on the final project outcome with additive technologies.

In this article, we’ll discuss what properties are affected by alloy selection, which factors can be influenced by powder design, and how process design contributes to the final part’s properties.

Teamwork to determine materials specifications is critical in additive manufacturing. We’ll discuss how collaboration can help maximize productivity and part quality for automotive and aerospace applications. The industry has already learned from successful additively manufactured production parts that the customer-supplier relationship is critical to optimize serial production.

In effect, with laser powder bed fusion (L-PBF) and many other additive technologies, you make the material as you form the part. L-PBF is, at its heart, a process of stacking many very tiny welds. It modifies the raw material as the piece is being built.

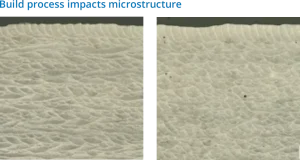

In many metal additive manufacturing technologies, decisions made about the build process strongly influence mechanical properties by defining the part density and microstructure of the material coming out of the printer. In contrast, with subtractive processes, these mechanical properties are primarily determined by raw material selection with well-defined standards for each metal coming from the mill. In both cases, heat treatments can be used to alter the final part properties, but they cannot correct for poor decisions in feedstock selection or process controls.

Material selection: what you need to know

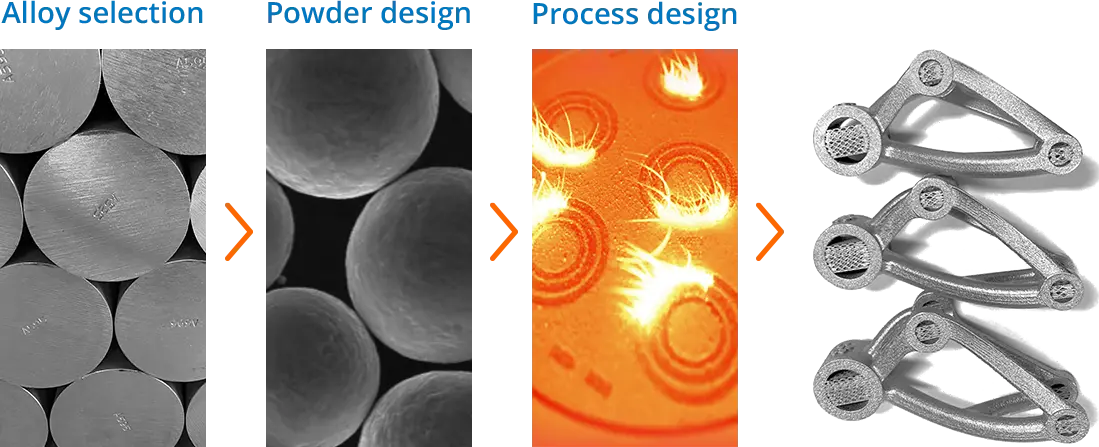

Material/alloy selection is only the beginning when planning an AM project. End part properties are determined by:

- Alloy selection

- Powder design

- Process design

Alloy selection defines the possible part performance. Each alloy will have a potential range for features such as mechanical strength, thermal behavior, corrosion resistance and surface treatment options, and electrical conductivity.

Alloy selection also sets the basic requirements for downstream processing, such as heat treatment. Finally, there will be tradeoffs between well-established alloy families and new alloys optimized for AM.

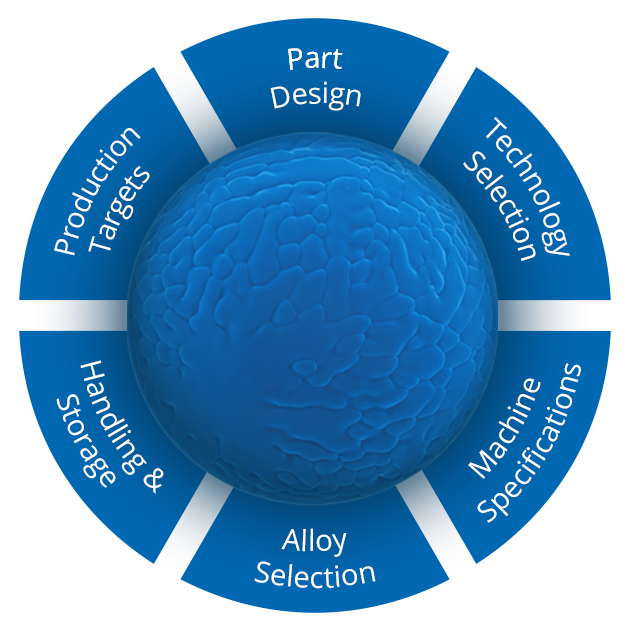

Once the alloy is selected, powder selection (in fact – powder design) is necessary to align the material input to an additive process with the end use application. In our experience with the automotive and aerospace sectors, the final application of the part directs the powder requirements. Depending on your materials supplier, some powder features can be fine-tuned for specific applications.

Considerations that affect powder design are:

- Design of the end-use part (features and geometry)

- Additive technology (L-PBF, directed energy deposition, binder jet)

- Machine specifications (laser power, spot size, gas flow)

- Alloy (volatiles, reactivity)

- Handling and storage considerations

- Production rate targets

With early and open collaboration, powder design can be optimized to achieve design performance targets and complete material and part qualifications (MQ/PQ) with highly repeatable results.

During the qualification phase, the data created will define the acceptable limits for manufacturing. In establishing the production process parameters, the interaction between powder, printer and process parameters define:

- Average and statistical mechanical properties

- Dimensional accuracy

- Surface roughness

- Heat treatability

- Throughput rate

Remember that default process parameters provided by AM machine vendors are generally a compromise, designed for generally good results across a wide range of part geometries, but not necessarily optimized for any one situation. Collaboration with the applications engineering team from your materials supplier can lead to parameter sets that better meet the particular needs of your project.

Consider the very common effect of heat extraction in the L-PBF process. The “optimal” energy to melt the powder bed is dependent not only on the material being built, but the geometry of the part. If there is a lot of solid volume below the layer being melted, there is (in many cases) more heat being extracted from the active area than in a thinner section, changing the required optimal energy input.

The properties of the powder being used also significantly affect the process. For example, Equispheres AlSi10Mg powder has been demonstrated to require approximately 20% less energy input than typical aluminum powders to achieve ideal melting in the L-PBF process. This opens the opportunity to increase laser speed (increasing build rates) when compared to a default parameter set. The robustness of our powders means that default parameters still work just fine, but by tuning laser speed, layer thickness, and other process parameters, we can almost always achieve better end results, whether the powder advantages are used to improve build speed, mechanical properties, or feature accuracy.

Collaboration continues INTO the production phase

So far, we’ve discussed alloy selection, powder design and process design considerations. Communication between the designer and the supplier is critical before material selection, but this collaboration can also have an ongoing role.

Where does collaboration fit once a decision has been made on the feedstock?

The qualification process requires a deep understanding of material behavior from start to finish. Suppliers with a dedicated applications engineering team are well-equipped to assist with qualification.

Collaboration with the materials supplier can reduce initial development time by sharing existing datasets and expertise. The supplier can also help establish the process controls for continued production, including aligning testing and quality assurance methodologies.

As anyone familiar with production quality assurance will tell you, control of process variation is at the heart of a good QA program. However, one challenge with the current state of the AM industry is that powder measurement standards defined for traditional powder metallurgy are not always sufficient for ensuring that powder feedstock is consistent in the ways that matter for AM processes. For example, the traditional “flow” tests for powder, using a funnel and measuring the time it takes for powder to flow through, do not really replicate the dynamic behavior of powder being deposited in an L-PBF, directed energy deposition (DED), or binder jet (BJT) process, and may not catch subtle changes in powder behavior that will affect the print consistency down the road.

Even where standardized test techniques are relevant, lab-to-lab and instrument-to-instrument variability are potential sources of QA issues once production begins.

These considerations are multiplied during production when we consider management of powder reuse from cycle to cycle. Working with your material supplier to establish measurements and controls for powder reuse is critical for cost-effective and reliable production.

While industry standards are an excellent supporting tool and becoming significantly more mature each year, working together with your supplier early on to define clear specifications for the specific application – and accepted test methods and procedures – is an important factor in ensuring a smooth transition to production, and ongoing program success.

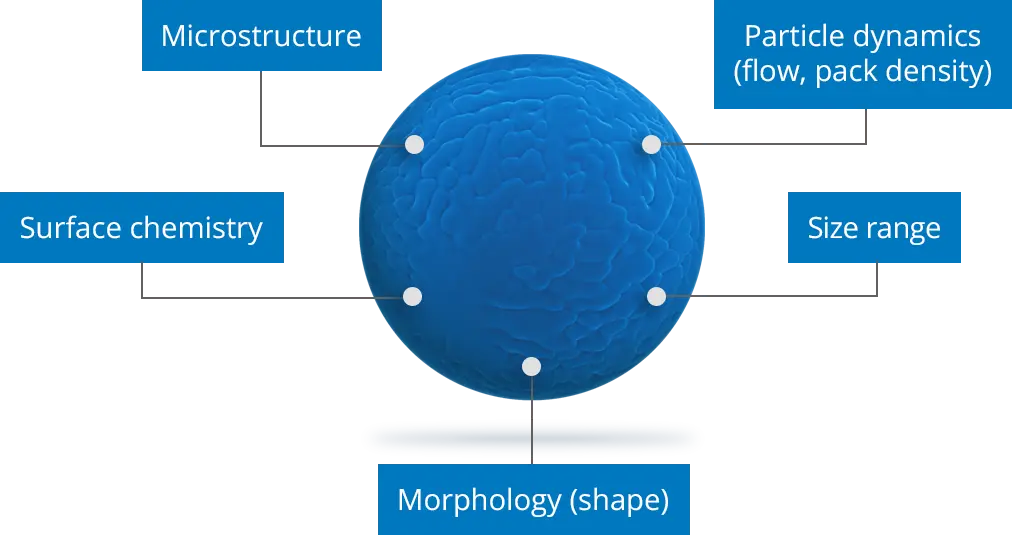

What is powder design?

We’ve talked a lot about powder design. Let me explain what we mean by that.

When people in the metal AM world talk about material design, they typically think specifically of new alloys. This, of course, is a very important path of development for AM to continue its growth, especially in aluminum, where the available range of off-the-shelf materials for L-PBF is quite limited (don’t worry, we’re working on this too).

In this case, the powder design we are referring to is the design of the actual powder particles in order to achieve desired behavior in a manufacturing process. This can include tuning the particle surface properties, size range, oxide content, and other factors to ensure the powder performs a specific way in the build process. This is an overlooked, but critical, aspect of material design for AM.

Equispheres’ NExP-1 is an example of powder design at work. It is a non-explosible, non-combustible printing media for AM, capable of maintaining a stable build process at very high powers and speeds. It was designed by Equispheres in response to the industry’s need for safer aluminum powders with fewer handling restrictions. As production sites adopt AM, manufacturers are challenged by the storage limitations and handling requirements for large quantities of aluminum alloy powder. Using a common alloy, we have produced a non-explosible powder that provides excellent print results under a wide range of conditions. This type of customization is what we mean by “powder design.”

Collaboration is the way forward

The customer-supplier relationship is critical to optimizing initial material selection and ongoing process controls, particularly in industries with rigorous quality systems, such as the aerospace and automotive sectors. Ongoing collaboration can speed up qualification and ensure alignment of quality assurance and testing protocols.

Teamwork and communication are the cornerstones of future growth in this rapidly evolving industry.

+ Connect with me on LinkedIn

+ Follow Equispheres on LinkedIn, Twitter, & Facebook