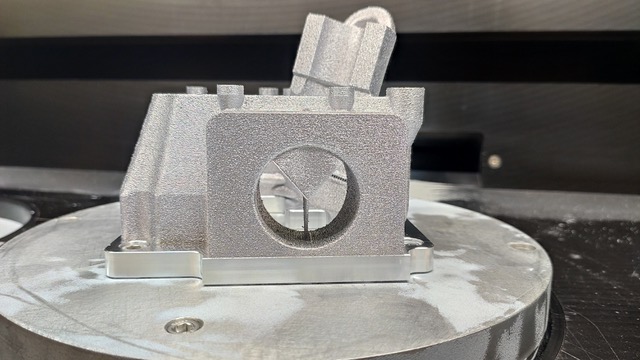

Integrating Passive Cooling for High-Efficiency Thermal Management

Automotive supplier Martinrea teamed up with Equispheres to redesign and rebuild an off-the-shelf e-motor housing. The award-winning project used optimized aluminum powder and LBPF control techniques for vastly improved thermal performance.

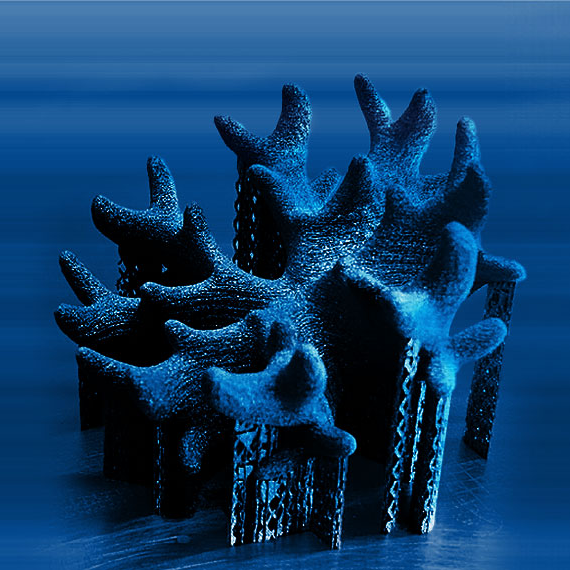

Revolutionizing Metal Additive Manufacturing: Faster Builds, Lower Costs, and Superior Surface Finish

A game-changing collaboration between Equispheres, Aconity3D, and Dyndrite has transformed metal additive manufacturing. Their innovations deliver 9x faster production, 80% cost reductions, and superior surface finishes, breaking longstanding trade-offs in speed, quality, and cost.

Case Study: Safer AM Powder Makes Aluminum Available for Innovators: Universities, SMEs

Researchers at SDU have successfully added aluminum to their AM capabilities using Equispheres’ NExP-1 AlSi10Mg, which was chosen for its safer storage and handling characteristics, as well as its reliable performance.

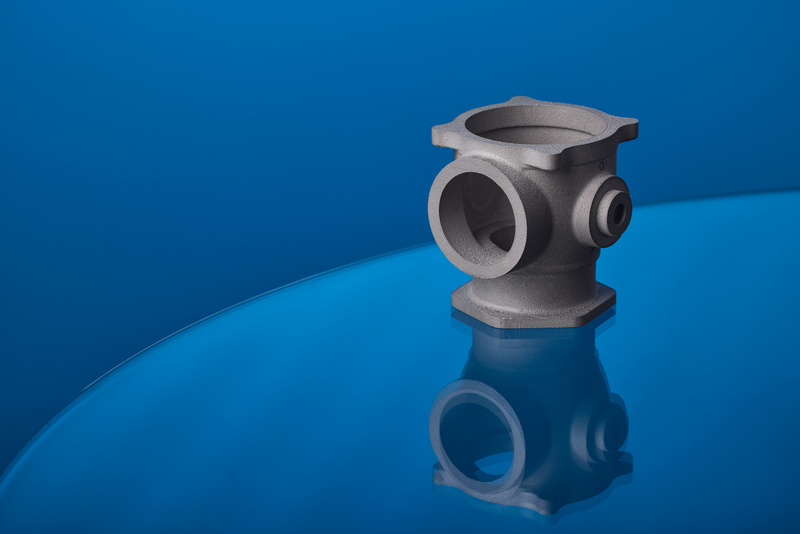

Case Study: The Need for Speed – Automakers Improve Production Time with High-performance Powders

Two automakers reveal how they have achieved significant increases in the production speed of aluminum parts made by additive manufacturing.

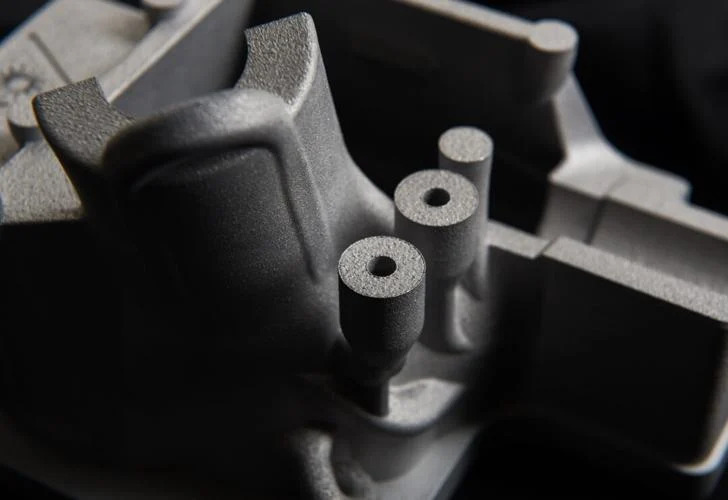

Case Study: Defense Contractor Achieves Higher Precision and Better Properties

For producers in the aerospace and defense sector, part performance, part reliability and cost are critical factors. This manufacturer confirmed it could reliably produce parts with higher dimensional accuracy and with superior mechanical properties.

Aconity3D: 3x Faster Print Speed for Industrial Component

Powders designed for traditional manufacturing AM processes allow for unnecessary variability. Modern powders are designed specifically for AM and are ideal for automotive manufacturing.