Integrating Passive Cooling for High-Efficiency Thermal Management

Automotive supplier Martinrea teamed up with Equispheres to redesign and rebuild an off-the-shelf e-motor housing. The award-winning project used optimized aluminum powder and LBPF control techniques for vastly improved thermal

Revolutionizing Metal Additive Manufacturing: Faster Builds, Lower Costs, and Superior Surface Finish

A game-changing collaboration between Equispheres, Aconity3D, and Dyndrite has transformed metal additive manufacturing. Their innovations deliver 9x faster production, 80% cost reductions, and superior surface finishes, breaking longstanding trade-offs in

Case Study: Safer AM Powder Makes Aluminum Available for Innovators: Universities, SMEs

Researchers at SDU have successfully added aluminum to their AM capabilities using Equispheres’ NExP-1 AlSi10Mg, which was chosen for its safer storage and handling characteristics, as well as its reliable

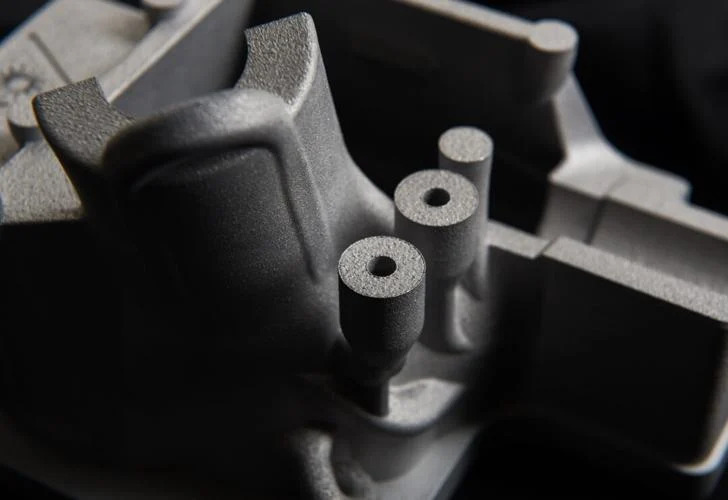

Case Study: The Need for Speed – Automakers Improve Production Time with High-performance Powders

Two automakers reveal how they have achieved significant increases in the production speed of aluminum parts made by additive manufacturing.

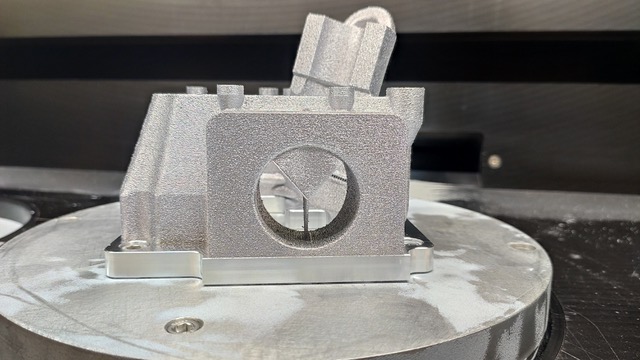

Case Study: Defense Contractor Achieves Higher Precision and Better Properties

For producers in the aerospace and defense sector, part performance, part reliability and cost are critical factors. This manufacturer confirmed it could reliably produce parts with higher dimensional accuracy and

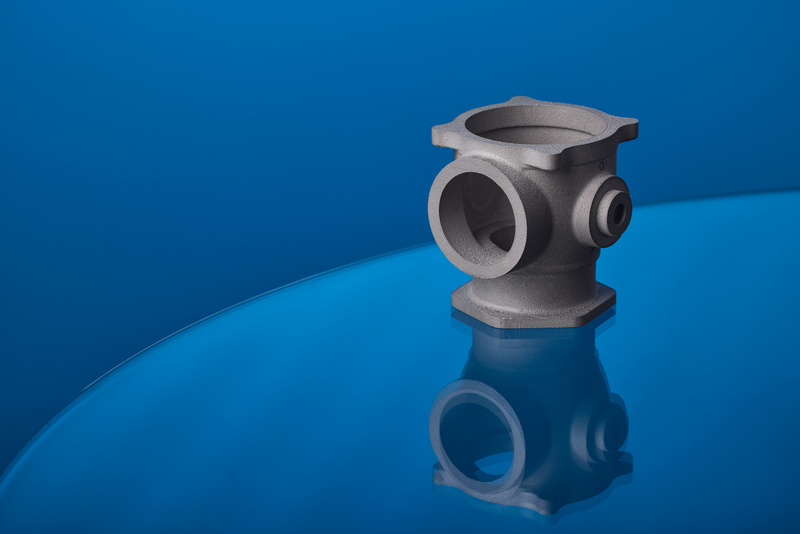

Aconity3D: 3x Faster Print Speed for Industrial Component

Powders designed for traditional manufacturing AM processes allow for unnecessary variability. Modern powders are designed specifically for AM and are ideal for automotive manufacturing.

Recommending Reading

Why PSD Matters: Getting to the Source of Surface Roughness in AM

A new study from researchers at McGill University uncovers the correlation between aluminum powder characteristics – specifically particle size distribution (PSD) – and sidewall surface roughness, a

Applying AM for Efficient E-Motor Thermal Management

Advanced aluminum powder enables a groundbreaking integrated cooling solution that uses Additive Manufacturing to reinvent thermal management.

Accessible Aluminum 3D Printing: New Research Validates Safety and Performance of Non-Explosible Powder

Facilities operating medium-wattage laser powder bed fusion (L-PBF) machines now have an alternative that offers both safety and performance. Research has shown that Equispheres NExP-1 aluminum powder can perform effectively

Academic Reading

Impact of Powder Size, Size Distribution and Morphology on Additive Manufacturing

What’s the secret to consistent parts? Dr. Conlon explains how various powder characteristics affect key mechanical properties in the final product—dimensional accuracy, hardness, surface roughness, tensile strength, yield strength, and

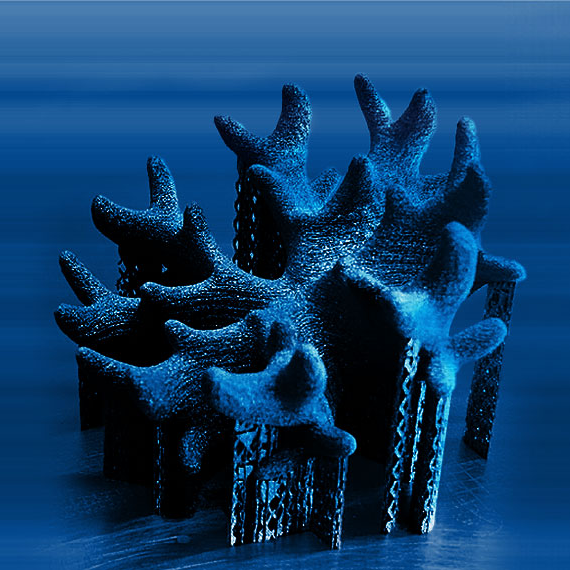

Understanding the Factors Influencing Powder Spreadability For Laser Powder Bed Fusion

Powder flow behaviour is an important aspect of the build process. How can we achieve good spreadability to create consistent powder layering and, ultimately, high-quality parts?