Innovative Materials Engineering Makes Aluminum a Safer Choice for Additive Manufacturing

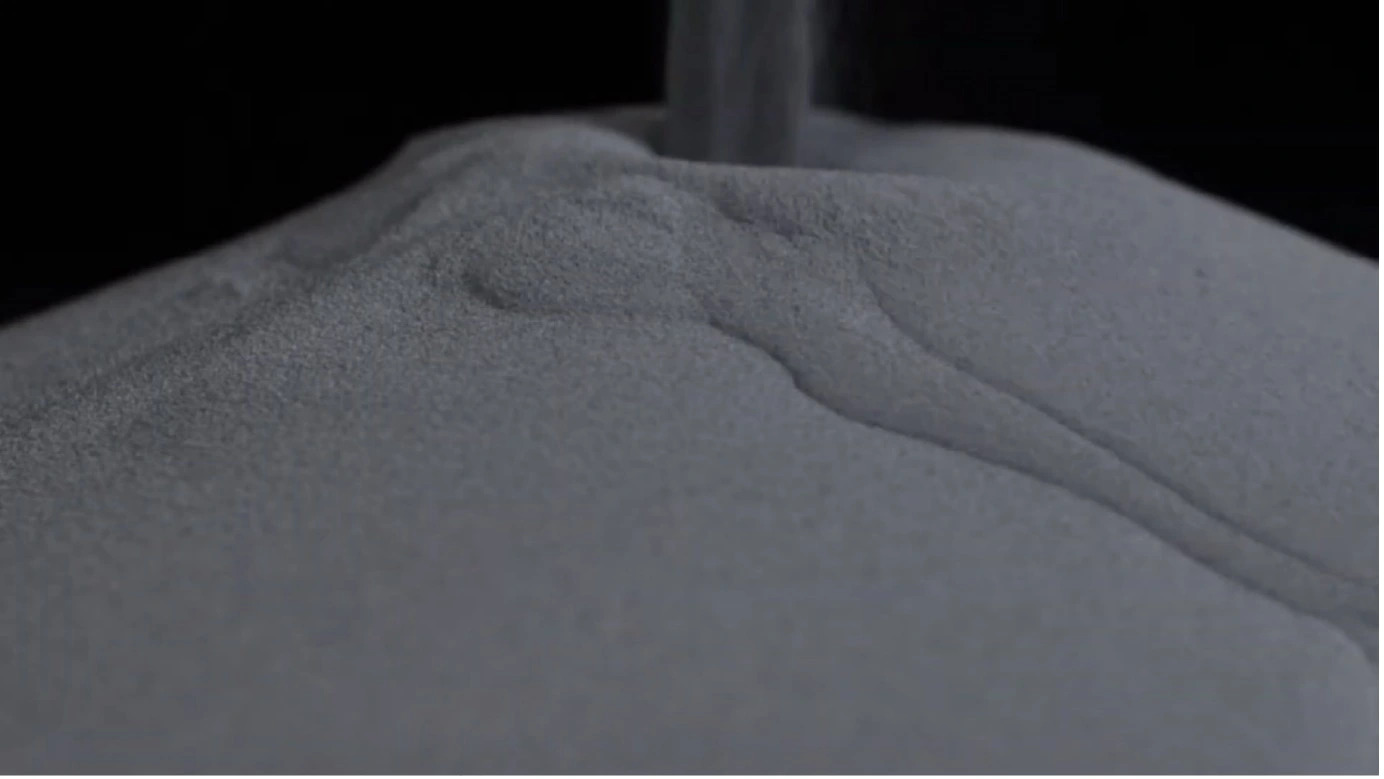

Equispheres minimized the risk of using aluminum powder for additive manufacturing by re-engineering the powder to be non-explosible.

How to Choose the Right Material for Efficient, Consistent Additive Manufacturing

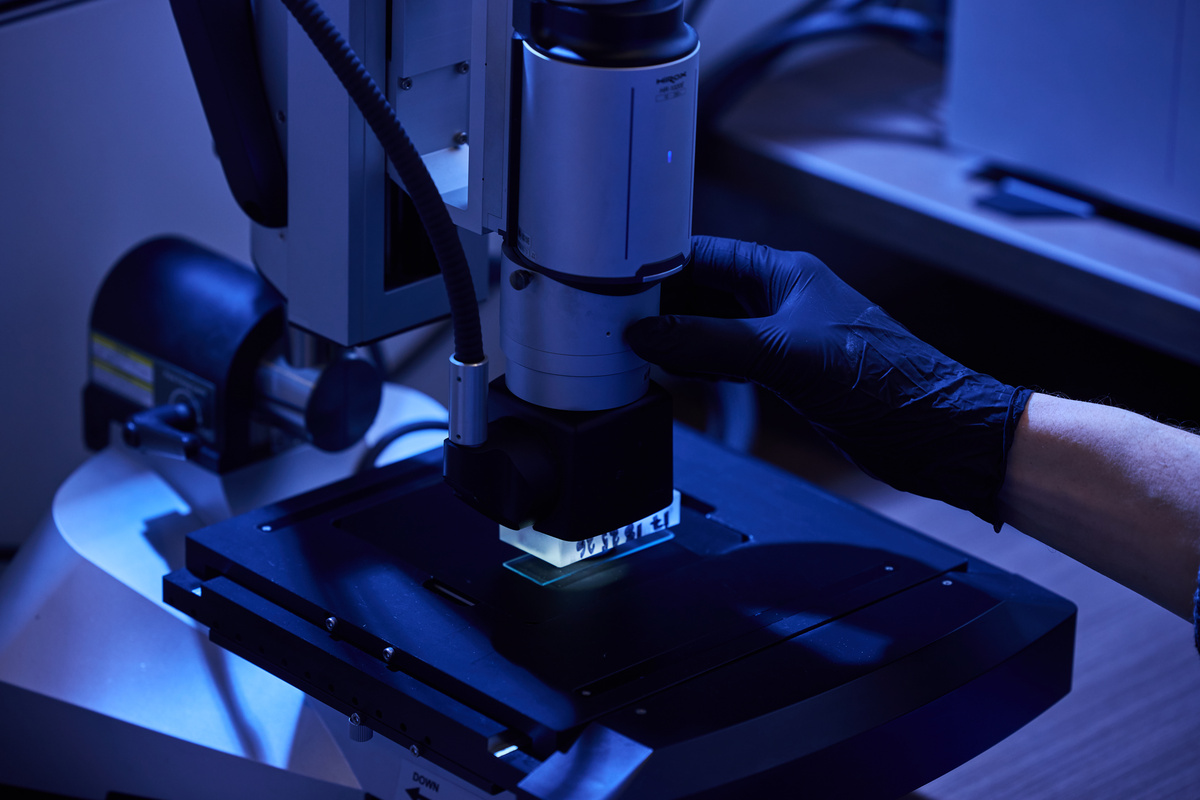

In powder-bed additive manufacturing (AM), the interaction between alloy selection, powder design and process design determines final part properties, so collaboration with materials suppliers is vital.

Beyond Safety: Non-Explosible Aluminum Feedstock is Simpler, Cleaner, Quicker for Additive Manufacturing

Equispheres’ non-explosible NExP-1 aluminum feedstock has standout safety characteristics for additive manufacturing, plus, it simplifies handling and storage protocols, speeds up machine cleaning and achieves high build rates.

Spheres Make All the Difference

Anyone operating 3D printers will appreciate the difference when working with engineered aluminum alloys from Equispheres – increased processing window, ease of printer cleaning, faster printing and consistent mechanical properties.