What the future is made of

The only future is a sustainable future – and Equispheres is fully committed to delivering products and services that minimize GHG emissions. As a pioneer in the development of a new and novel powder production technology, the company took the opportunity to ensure sustainability was at the core of our development process. The result is a tangible sustainability plan that encompasses the full lifecycle of materials, manufacturing and part end-use application. From powder production to powder application through to final part utilization – our approach is already delivering results.

The core pillars of our sustainability plan are:

- Low GHG (greenhouse gas) supply chain – we collaborate with suppliers based on sustainability values:

- Green metal ingot feedstock providers with 85% lower GHG emissions per kg of material

- Electrical energy from power grids that are over 90% carbon-free

- Efficient powder production – our new technology achieves an exceptionally high yield and consumes approximately 40% less power than conventional processes

- Efficient part production

- Higher print efficiency resulting 20% less energy consumption to produce parts

- High re-use rates of powder (Powders designed for minimal in-production waste)

- High-impact GHG applications – we have targeted our solutions to the Transportation sector, which is responsible for 25% of all worldwide GHG emissions. Higher print efficiency resulting in 20% less energy consumption to produce parts

- Superior part light-weighting (up to 50 – 60% less part mass) – resulting in a significant reduction in end-use GHGs

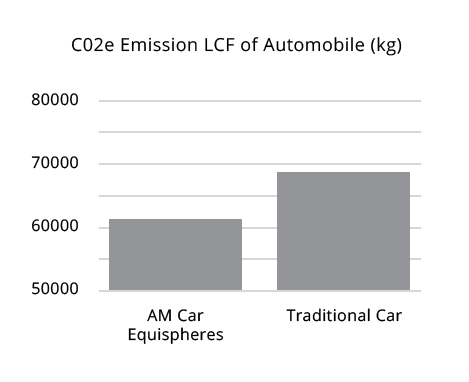

The results are real and measurable. In a typical transportation application, the total GHG emissions over the lifetime of the part can be meaningfully reduced.

The work is always on-going, and Equispheres continues to collaborate with our partners and suppliers to achieve further advancements in sustainable manufacturing.