Read below for the latest news about our product and applications, as well as upcoming events where you can meet us in person. Sign up for our email list to have news and announcements delivered to your inbox.

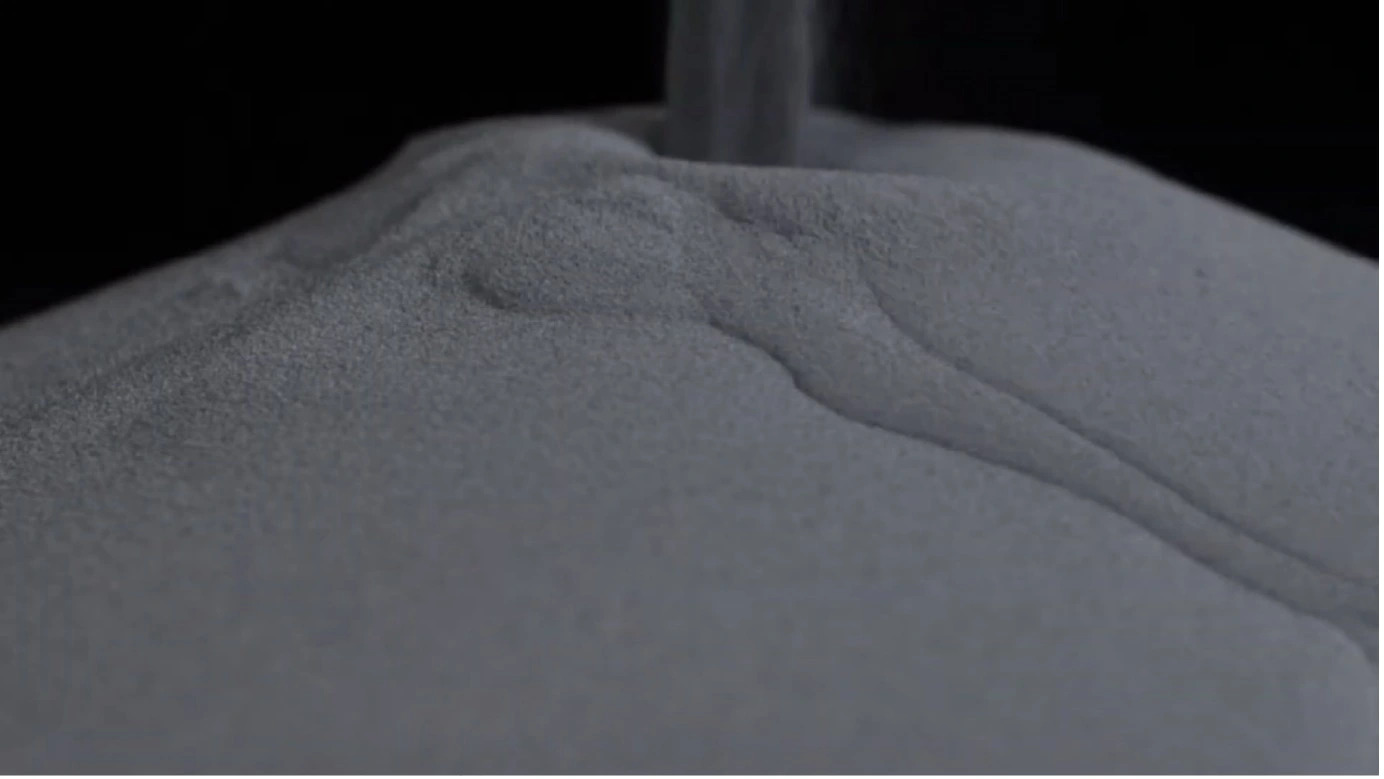

Why PSD Matters: Getting to the Source of Surface Roughness in AM

A new study from researchers at McGill University uncovers the correlation between aluminum powder characteristics – specifically particle size distribution (PSD) – and sidewall surface roughness, a key contributor to fatigue failure.

Applying AM for Efficient E-Motor Thermal Management

Advanced aluminum powder enables a groundbreaking integrated cooling solution that uses Additive Manufacturing to reinvent thermal management.

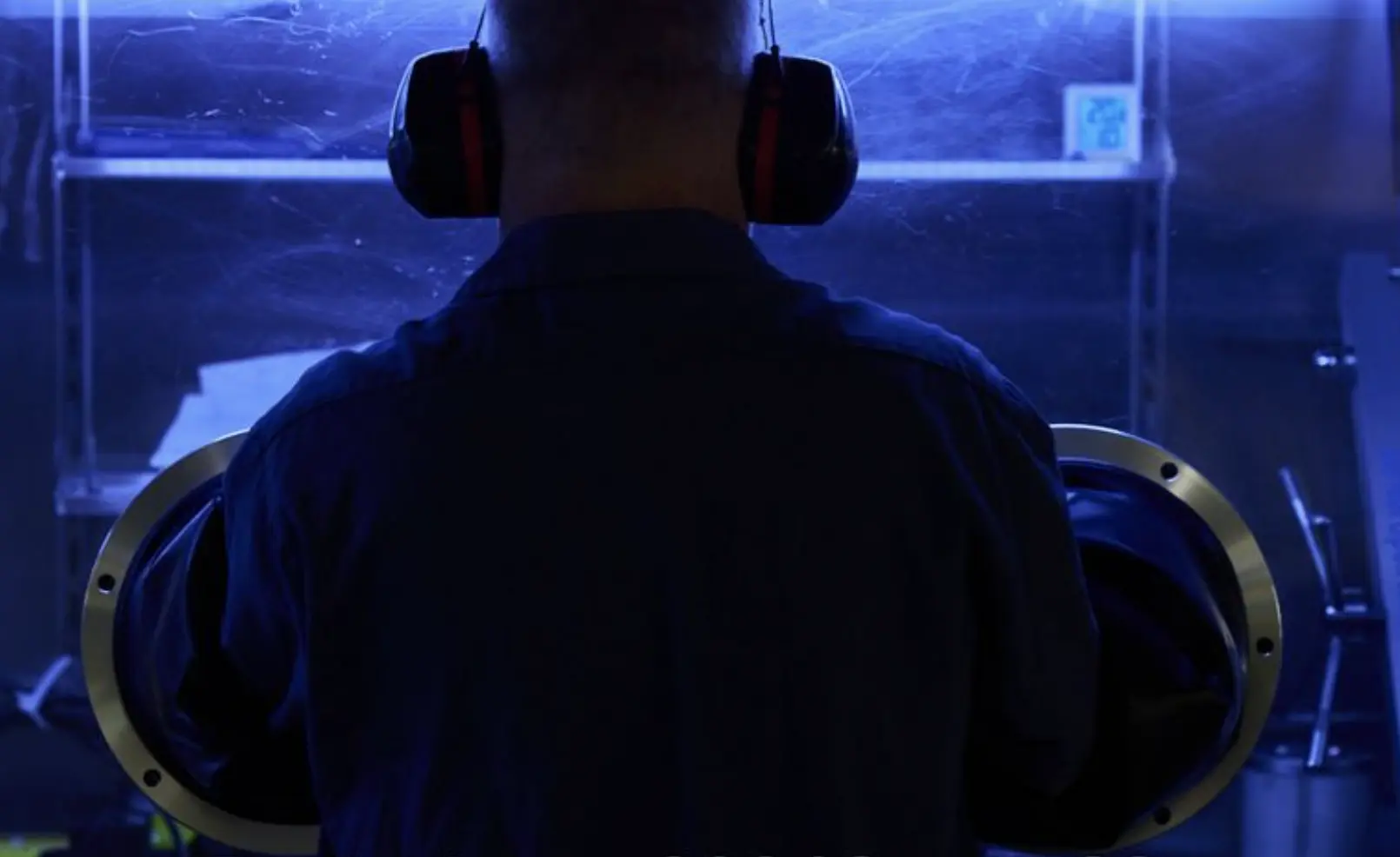

Accessible Aluminum 3D Printing: New Research Validates Safety and Performance of Non-Explosible Powder

Facilities operating medium-wattage laser powder bed fusion (L-PBF) machines now have an alternative that offers both safety and performance. Research has shown that Equispheres NExP-1 aluminum powder can perform effectively even on more affordable 400W systems—potentially expanding aluminum AM to organizations that previously couldn’t justify the safety infrastructure costs.

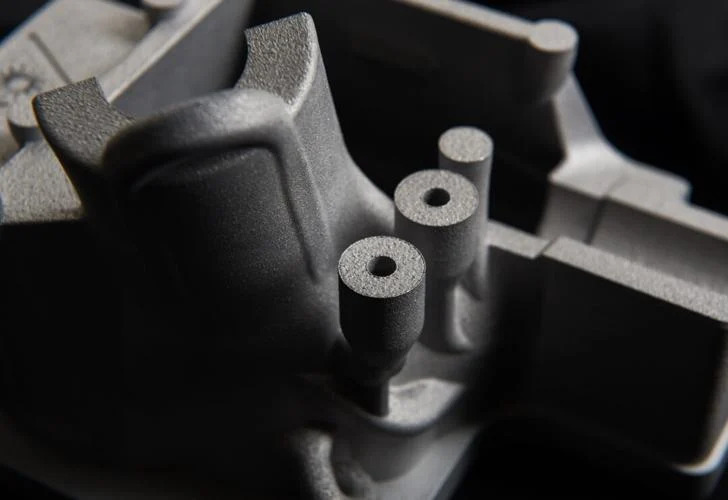

Heat-treating aluminum AM parts? Here’s how to avoid thermal-induced porosity and blistering

Traditionally seen as risky for additively manufactured aluminum, T6 heat treatment often causes blistering due to thermal-induced porosity. Equispheres’ engineered aluminum powders, however, significantly reduce this issue by minimizing trapped gases, allowing parts to undergo heat treatment without defects. Recent tests show Equispheres powders outperform competitors in porosity control, helping aerospace and AM industries move closer to reliable, high-performance aluminum components.

Innovative Materials Engineering Makes Aluminum a Safer Choice for Additive Manufacturing

Equispheres minimized the risk of using aluminum powder for additive manufacturing by re-engineering the powder to be non-explosible.

What’s the Secret to 9x Faster Throughput in L-PBF? Designer Powder and Laser Beam Shaping

Equispheres and Aconity3D developed a high-throughput laser powder bed fusion process that delivers breakthrough print speeds, supported by Equispheres’ AM-optimized aluminum powders.

How Beam Shaping Will Take Metal AM to the Next Level

The next leap forward in metal additive manufacturing (AM) has arrived in the form of laser beam shaping. The combination of beam shaping and designer metal powders for AM has resulted in remarkable increases in productivity for Laser Powder Bed Fusion (L-PBF) processes.

How to Choose the Right Material for Efficient, Consistent Additive Manufacturing

In powder-bed additive manufacturing (AM), the interaction between alloy selection, powder design and process design determines final part properties, so collaboration with materials suppliers is vital.

Beyond Safety: Non-Explosible Aluminum Feedstock is Simpler, Cleaner, Quicker for Additive Manufacturing

Equispheres’ non-explosible NExP-1 aluminum feedstock has standout safety characteristics for additive manufacturing, plus, it simplifies handling and storage protocols, speeds up machine cleaning and achieves high build rates.