We are known for our high-performance metal powders, but first and foremost Equispheres is a materials science engineering firm. Our deep knowledge of metallurgy and metal technology is what allows us to produce powders with the performance and properties we do. By sharing our research, insights and white papers we hope to help the entire industry advance faster and achieve more, sooner. Browse all available papers and reports below or contact us for any specific queries or to talk to one of our Materials Science Experts.

Whitepaper: The Problem With Additive Metal Manufacturing

The promise of additive manufacturing (AM) as a disruptive technology has been discussed in engineering circles for decades and promoted in the mainstream media for years. The benefits of AM

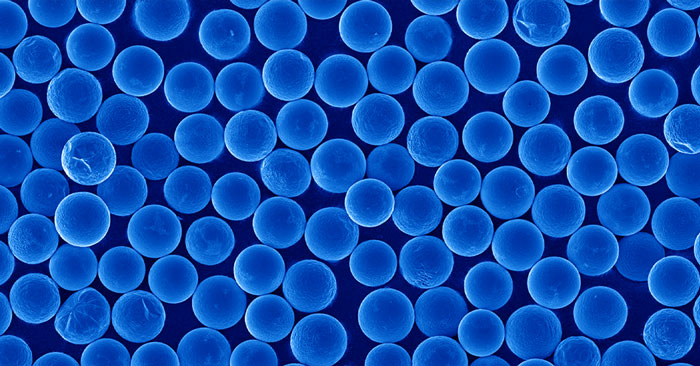

Impact of Powder Size, Size Distribution and Morphology on Additive Manufacturing

What’s the secret to consistent parts? Dr. Conlon explains how various powder characteristics affect key mechanical properties in the final product—dimensional accuracy, hardness, surface roughness, tensile strength, yield strength, and

High-Performance Aluminum Powder: Fueling Metal AM Market Growth

Learn how our innovative, high performance aluminum powder is pushing the metal additive manufacturing market forward.

Understanding the Factors Influencing Powder Spreadability For Laser Powder Bed Fusion

Powder flow behaviour is an important aspect of the build process. How can we achieve good spreadability to create consistent powder layering and, ultimately, high-quality parts?