Webinar: Accelerating Metal Additive Manufacturing – the Importance of Powder / Printer Combination

Modern high precision and highly controllable powder-bed fusion printers combined with specialized powder specifically tailored for AM can significantly increase the speed of part production and dramatically reduce costs.

In this webinar, learn how to improve Aluminum L-PBF productivity by leveraging the unique attributes of Equispheres proprietary metal powder.

Webinar: Improving Performance and Quality in Aluminum Additive Manufacturing

Increasing productivity in metal additive manufacturing will accelerate the widescale adoption of the technology in manufacturing. As the technology matures, it is becoming increasingly evident that the feedstock used in Laser-Powder Bed Fusion (L-PBF) is a primary factor driving the limits of the process.

In this webinar, learn how to improve Aluminum L-PBF productivity by leveraging the unique attributes of Equispheres proprietary metal powder.

Trends in Metal Additive Manufacturing: The Importance of Powder

Panel discussion on the importance of powder to metal additive manufacturing with a very diverse group of experts that span the spectrum from powder production, all the way to powder use. Our panellists: Filip Francqui – Granutools, Simon Pun – Divergent 3D, Dr. Mathieu Brochu – McGill University, Dr. Martin Conlon – Equispheres

Whitepaper: The Problem With Additive Metal Manufacturing

The promise of additive manufacturing (AM) as a disruptive technology has been discussed in engineering circles for decades and promoted in the mainstream media for years. The benefits of AM – design freedom, weight savings, assembly simplification, economic batch size reduction – have all been achieved to some degree by those adopting the technology.

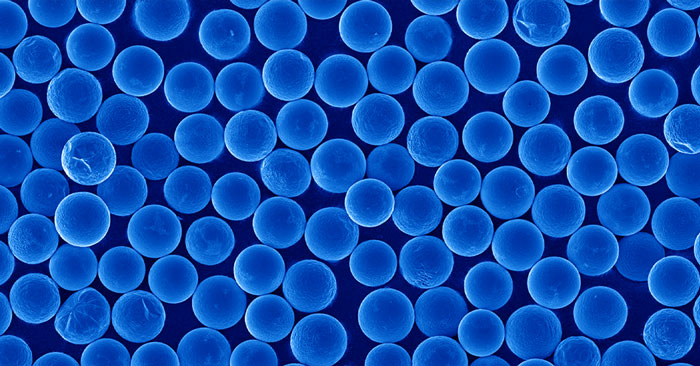

Impact of Powder Size, Size Distribution and Morphology on Additive Manufacturing

The morphology and consistency of metal powder feedstock has a profound impact on the quality, integrity and reliability of parts produced using additive manufacturing. Analysis and tests conducted using AlSi7Mg powder provided by various suppliers in both powder-bed and direct energy device printers have identified the influence and importance of powder characteristics such as particle size, size distribution, sphericity, oxide layer thickness, microstructure, fines, agglomerates and surface condition on the resultant additively manufactured part.

High-Performance Aluminum Powder: Fueling Metal AM Market Growth

Learn how our innovative, high performance aluminum powder is pushing the metal additive manufacturing market forward.

Understanding the Factors Influencing Powder Spreadability For Laser Powder Bed Fusion

Powder flow behaviour is an important aspect in powder-based additive manufacturing technology, which relies on good spreadability to obtain a consistent powder layering that will ultimately result in high-quality parts.