Researchers at SDU have successfully added aluminum to their AM capabilities using Equispheres' NExP-1 AlSi10Mg, which was chosen for its safer storage and handling characteristics, as well as its reliable performance.

Getting started in metal additive manufacturing is easier than ever. With the tremendous growth metal AM has experienced in recent years, the technology has become more accessible. Suppliers have expanded their product offerings and have more real-world expertise to draw from.

For small enterprises, universities, or research organizations, it’s a matter of choosing versatile, easy-to-use equipment and materials, and finding the right partners to support the journey.

Using technologies from Equispheres Inc. and Xact Metal, a team from the University of Southern Denmark (SDU) recently expanded its capabilities into Laser-Powder Bed Fusion (L-PBF) of aluminum. SDU had previous experience with other metals using Xact Metal’s high-quality, low-cost XM200G 3D printer, but they had been reluctant to use aluminum because of safety concerns.

Conducting industrial processes in a university setting can be challenging. There are students of varying skills and experience levels working in the lab, frequent changes of projects and materials, and a broader range of materials and chemicals may exist than in a typical manufacturing environment.

Using Equispheres’ non-explosible NExP-1 AM material instead of other aluminum powders more closely lined up with the risks the university was accustomed to when using steel powder or other AM feedstocks.

Safer AM powder to the rescue

SDU’s additive manufacturing lab focuses on mechatronics and additive manufacturing integration. The lab began exploring AM with plastic materials and later moved into laser powder bed fusion with the Xact Metal system.

The SDU team had frequently been asked to manufacture aluminum parts. Still, administrators were concerned about the safety of reactive materials such as aluminum and titanium and the hazards associated with aluminum powder and dust.

It wasn’t until Equispheres introduced its NExP-1 AM printing medium in 2022 that the group felt confident to proceed with aluminum parts. NExP-1 is a non-explosible AlSi10Mg material with less restrictive storage and handling considerations. It opened the door for SDU to begin working with aluminum.

While safety was the key consideration for SDU, the wide processing window and general ease of printing with NExP-1 was a major benefit in achieving a rapid and successful start. NExP-1 was designed for high-volume production applications in automotive and other sectors that require fast build speeds and highly consistent behavior, features that were also beneficial for the team at SDU who were using the material for the first time on the Xact Metal system.

"Barriers to the use of metal AM are falling. This project illustrates that there are options that make additive manufacturing available to producers wherever, whenever they want."

– Evan Butler-Jones, Vice-President – Product & Strategy for Equispheres.

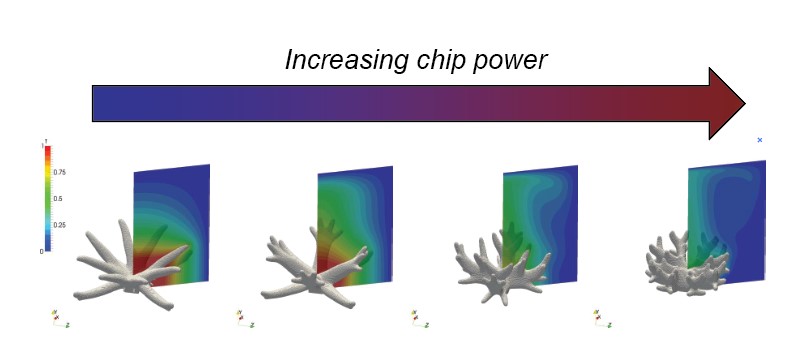

The part SDU chose to launch its aluminum journey is a heat sink with a challenging design. The part is generatively designed, with organic shapes and curves that would be difficult to produce with anything but additive manufacturing.

“This project was our first attempt at printing reactive powders,” says Andrei-Alexandru Popa, Additive Manufacturing Lead and Assistant Professor at the University of Southern Denmark. “The safer handling characteristics of Equispheres’ NExP-1 powder made us feel more comfortable using aluminum powder in a university lab setting.”

According to the 2022 Wohlers Report, almost 12% of industrial additive manufacturing systems are used in education and research. Supporting this niche fosters the growth of new talent and fresh ideas for the industry.

Heat sink is a natural fit for high-performance aluminum powder

The heat sink developed by SDU, which looks like a piece of coral, is designed to draw heat away from computer chips and electronic components. The SDU team built prototypes of the part from plastic, and then attempted to print functional parts using steel and copper. Both had drawbacks. Aluminum was the optimal material for this design, but the team wasn’t permitted to use it because of safety concerns. All of that changed when Popa heard about NExP-1.

Evan Butler-Jones, Vice-President, Product & Strategy for Equispheres, recalls the early talks with Popa. “They were concerned about what it would take to use aluminum safely, especially because this is a university. Students work in the lab, and the university does a lot of projects for local businesses. They are rightfully very cautious about ensuring the learning environment is safe.”

An innovative material and a feature-rich, affordable metal printer proved to be the combination SDU needed to produce this complex part. The university’s success demonstrates that metal AM can be accessible to small- and medium-sized businesses, academia and research facilities.

Popa says: “For me, the greatest part of this aluminum adventure is the enthusiastic support from our partners, especially when we’re doing unholy things with their machines and powders. This “let’s make it happen” attitude sets these two companies apart. Now, with their help, we’re looking forward to expanding our manufacturing capabilities at the Centre for Industrial Mechanics (SDU).”

SDU uses an XM200G laser powder bed fusion printer from Xact Metal. With its affordable metal AM equipment, Xact Metal aims to help more designers, developers, and manufacturers experience the benefits of high-quality metal 3D printing. Its equipment is cost-effective, designed for quick adoption, and easy to use.

Team provided advice on storage and handling of aluminum powder

“Our applications engineering team and Xact Metal worked with SDU to make sure they had what they needed to be successful,” says Butler-Jones. “They had specific questions on handling the material, machine settings, etc., but once they were comfortable from a safety perspective, the team at SDU really took the ball and ran with it.”

Even with the simplified storage considerations of NExP-1, the lab had to implement specific safety measures to ensure overall health and safety for the employees and students, including processes for filter changes and powder cleanup to prevent cross-contamination.

SDU is applying for ATEX certification (a European Union directive for protection against explosive atmospheres). They were excited to learn that this high level of explosion prevention protocols was unnecessary for Equispheres’ NExP-1 AM printing material. This can be a time- and cost-saving feature for manufacturers looking to work with aluminum alloys.

High-performance aluminum unlocks new opportunities for SDU

Equispheres’ NExP-1 material allowed SDU to add aluminum to its repertoire and better serve its industry partners. NExP-1 may also create opportunities for metal AM in other environments where the storage of large amounts of reactive materials is problematic, including defense applications and smaller enterprises.

In addition to occupying a unique niche for ease of storage and handling, NExP-1 is a highly engineered powder with outstanding print characteristics. SDU has achieved better results with NExP-1 than the typical advertised properties for aluminum.

“The positive results experienced by Andrei-Alexandru and the team at SDU are consistent with what we’ve seen with industrial, multi-laser printers using NExP-1,” says Butler-Jones. “NExP-1 retains the best characteristics of a high-performance AlSi10Mg aluminum powder – faster print speeds and consistent mechanical properties – plus it makes equipment clean-up quicker and easier.”

How engineered aluminum AM powder helped SDU

NExP-1’s productivity-enhancing characteristics

- Best-in-class build rate

- Consistent mechanical properties

- Faster, easier machine clean-up

- Simplified storage and handling

The SDU team is having great success with NExP-1 and the Xact Metal printer. This pairing has opened up the possibility of new projects, programs, and parts made of aluminum.

With the combination of purpose-designed AM powders, affordable, high-quality machinery, and engineering support, the benefits of metal additive manufacturing are now within reach of more organizations.