The time has come for aluminum as a cost-effective, consistent and reliable solution for additive manufacturing service providers

Originally published by 3dpbm in the AM Services 2021 eBook

When it comes to material selection for metal additive manufacturing, aluminum and titanium share some key attributes. Both are light, strong and corrosion-resistant. In the past, their differences became evident once they were used in a 3D printer. While titanium tended to be quite robust to process, aluminum was notoriously difficult to print reliably, and therefore, qualified parameters tended to be limited. As a result, many AM applications more suited to aluminum have often been produced from titanium, despite the higher material cost.

However, some new aluminum powders can achieve similar AM processing qualities to titanium, providing much wider processing windows and reliable prints. These improvements give service bureaus more feedstock options. The availability of high-performing aluminum powder also has other significant implications for service bureaus. Most importantly, these materials can achieve higher build rates than traditional aluminum powders and can reduce the cost of producing an aluminum part by 50% with no impact on mechanical qualities.

Higher production rates and lower production costs provide AM service providers an opportunity to win more business and offer lower prices to customers.

The hope vs. the reality of aluminum in AM

About five years ago, metal AM began to make substantial inroads to both medical and aerospace applications. There was considerable enthusiasm in the industry, as additive technology was being used to make production aerospace components and artificial joints. The main material was titanium, with a few other exotic materials, such as Inconel™ and cobalt chrome alloys.

Industry experts were predicting that new alloys for AM would be quickly developed and widely used. Aluminum alloys were of particular interest as they have a high strength-to-weight ratio (making them suitable for aerospace and lightweight cars) and aluminum is the second most used industrial metal. Sadly, this vision did not materialize.

Users discovered that their favorite aluminum alloys (e.g. 6061, 7075, 2024) could not effectively be 3D printed, as these materials were prone to cracking when additively manufactured. As a result, the industry had to accept the lower-performing casting alloys, such as A357, for additive processes. Compounding the alloy selection limitations, these available aluminum feedstocks had two major drawbacks:

- They produced a wide standard deviation with regard to key mechanical properties of the finished parts, which negatively impacted the a-basis design allowable achievable by these materials and reduced their appeal to the aerospace sector; and

- They were finicky and had to be printed slowly, which drove up the cost per part, making metal AM economically unfeasible for most applications.

At the time, the AM industry had to accept an inefficient and substandard casting alloy with unreliable performance characteristics.

Now, as printers are becoming more powerful with higher wattage lasers, the quality issues with traditional aluminum powders are becoming even more apparent. Though printers are capable of higher laser energy and thicker layers, these aluminum powders derived from casting alloys cannot absorb the higher laser energy without significant disturbances to the melt pool, resulting in poor density and part quality.

The problem with aluminum powder

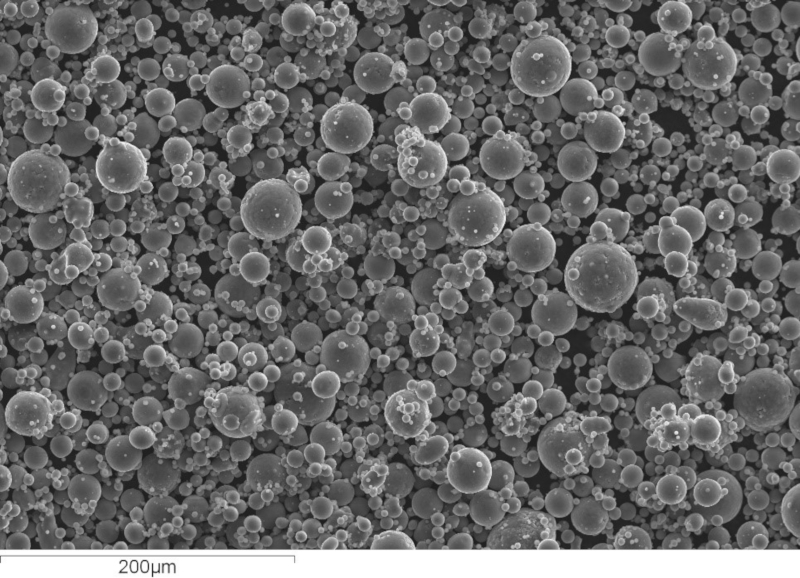

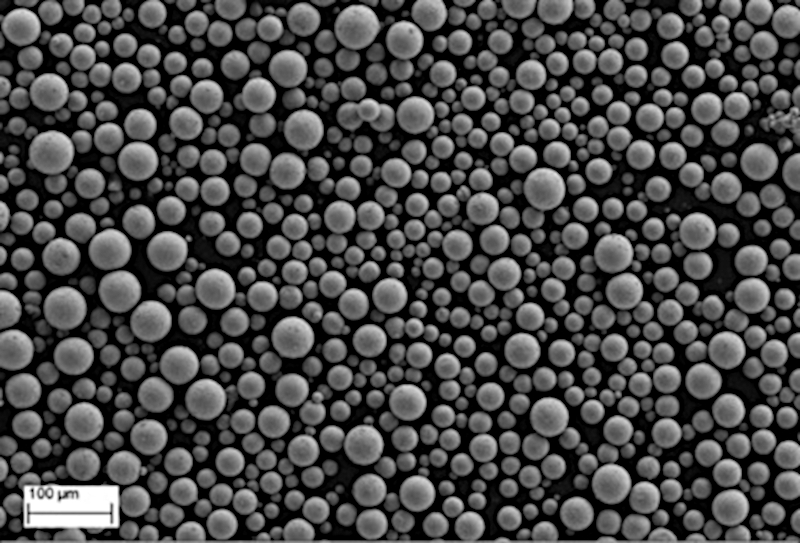

The reason aluminum powder is so difficult to process can be readily seen with a scanning electron microscope (SEM). Provided in Figure 1 is an image of traditional aluminum AlSi10Mg powder. Compare that with the similar image of Ti-6Al-4V titanium provided in Figure 2. As shown, the aluminum powder has a wide range of particle sizes, oblong shapes, agglomerates and an abundance of “fines”. The Ti powder, on the other hand, exhibits greater sphericity and superior morphology. As a result, the Ti powder enables a more stable and predictable melt pool which facilitates greater reliable mechanical properties.

Not all aluminum powder is created equal

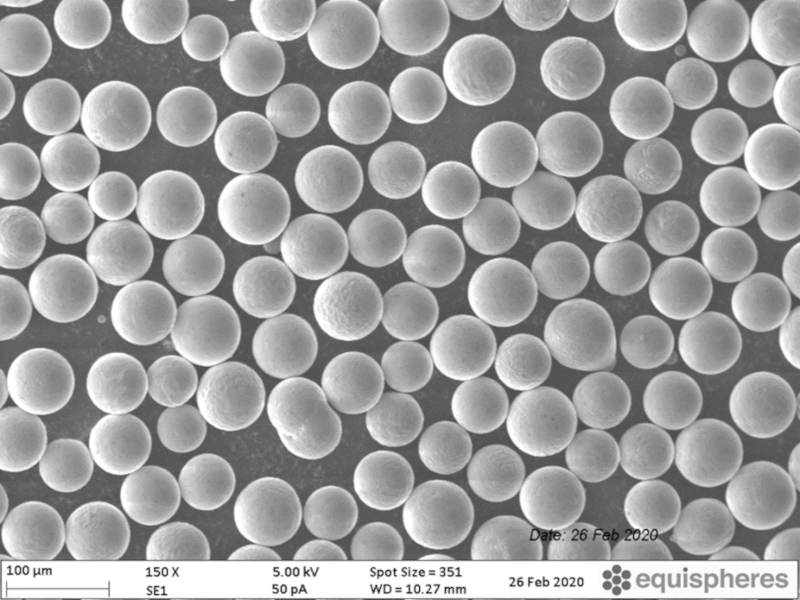

That said, some aluminum powders can achieve particle characteristics that meet and exceed those of Ti powder. Equispheres, for example, uses a patent-pending atomization process to create a range of aluminum powder alloys that are spherical and free of agglomerates and fines. These materials also have a thin oxide layer and uniform particle size. Provided in Figure 3 is an SEM photo of Equispheres’ aluminum alloy powder.

Unsurprisingly, this aluminum feedstock exhibits processing qualities more akin to those historically experienced with titanium.

Feedstock consistency leads to faster processing

The new crop of modern, high-performance aluminum powders, created via specialized atomization techniques, have very different processing characteristics than their predecessors. To fully realize the processing benefits of these newer powders, some materials science companies are offering engineering assistance to smooth the transition and ensure the material is being used to its full potential.

It is understood in additive manufacturing that successfully increasing layer thickness and scan speed for laser powder bed fusion depends on the stability of the melt pool. Being spherical and uniformly sized, these newer aluminum powders pack more densely and they absorb the laser energy evenly and efficiently. This produces a consistent melt pool at a variety of build rates, which enables operators to spread thicker powder layers and increase scan speed and hatch distances. These characteristics improve build rates by a factor of 2 to 4.

For AM service bureaus, these aluminum powders provide:

- Ease of processing and larger processing windows

- Faster build rates and lower costs

- Consistent and reliable mechanical properties.

By way of example, Precision ADM is a leading service bureau located in Canada that manufactures critical components and devices for the aerospace, defense, medical, automotive and energy sectors. Their customers are demanding so the company needs to ensure that the powder they work with can meet their customers’ high specifications. In their first evaluations of Equispheres AlSi10Mg powder they have been able to show that it is a viable feedstock option for processing at 60 μm layers with default processing parameters on an EOS M290 laser powder bed fusion (L-PBF) machine. In continuing evaluations, they have found viable processing parameters at 80 μm layers providing an increase in build rate. Using the Equispheres powder on their L-PBF platform has also provided cost and lead time reductions in component manufacturing that can then be transferred to their customer base.

In summary, the current phase of evaluation has provided the following observations:

- Ease of processing with more than 99.90% density achieved for processing at 60 µm and 80 µm layers.

- Faster AlSi10 Mg build rates up to at least 45.9 cm³/hr. when processing at 80 µm layers, in comparison to the 39.20cm³/hr. build rate at 60 µm on an EOS M290.

- Ti6Al4V build rate for 60 µm layer processing is at 32.40 cm³/hr. for an EOS M290 platform.

Precision ADM and other AM operators are taking advantage of these new high-performance aluminum powders. It’s clear that aluminum is once again poised to make inroads in the aerospace, automotive and defense sectors. This time, aluminum powders have been purpose-built to make additive manufacturing more efficient and reliable.