Winner of the 2025 AMUG Technical Competition in the Advanced Concepts Category

It’s always a highlight to see the latest innovations in Additive Manufacturing (AM) profiled in the annual AMUG Technical Competition, held this spring in Chicago. The Advanced Concepts category looks for creative, novel approaches that showcase the benefits of AM technology and workflows along with the design talent and process expertise required to develop new applications.

This year, Equispheres submitted the winning project in a collaboration with global automotive supplier Martinrea International that applied a novel AM process to improve thermal management in an e-motor housing. The aluminum demonstration part integrates two-phase passive and active cooling into a single structure — eliminating the need for external heat pipe assemblies and improving heat transfer efficiency.

It’s a great example of how AM can solve real-world engineering challenges that conventional manufacturing can’t address, uncovering the potential for use cases in Electric Vehicles (EVs) and other industries with thermal management concerns.

The innovation: passive and active cooling in a single printed structure

Combining creative design with advanced aluminum powder and laser powder bed fusion (LPBF) control techniques, the Martinrea-Equispheres team redesigned and rebuilt an e-motor housing that significantly improves thermal performance while staying within the packaging envelope of a production system.

While existing thermal management solutions often rely on larger pumps or increased coolant flow, passive cooling is more efficient and can actually improve the driving range of the e-motor.

In a key innovation, the demonstrator part integrates vapor chambers — a type of passive heat spreader—directly into the part during printing. The optimized LPBF process combined incomplete melt techniques with full-density printing to produce a fully functional, passively cooled vapor chamber within the e-motor housing.

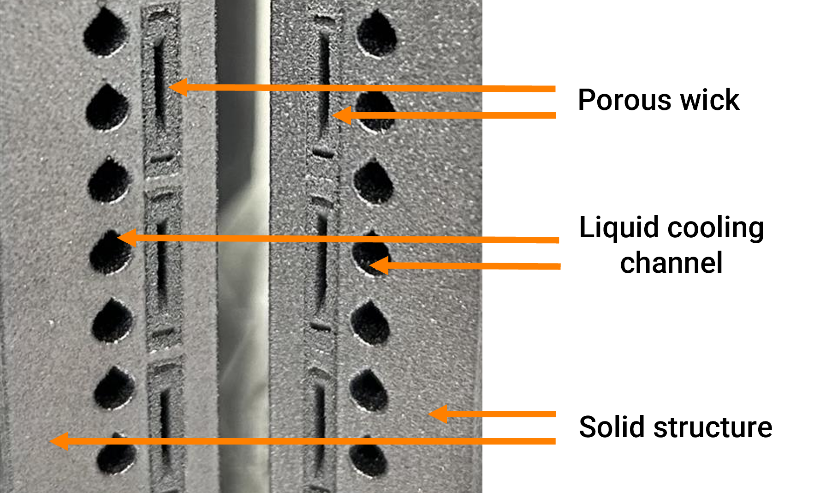

The technical challenge: build up the wick during printing

Vapor chamber functionality derives from a porous wicking region lining the chamber. Equispheres engineers developed a novel printing methodology to selectively build up the wick concurrently with the fully dense body in each slice of the print. This approach resulted in a wick structure capable of pumping liquid (one phase of a two-phase evaporation-condensation cycle).

The project also leveraged the uniformity of Equispheres aluminum powder to develop the parameters and build process for consistent wicking behavior on the AconityTWO printer. This delivered high permeability and small pore size comparable to commercial heat pipe wicking surfaces while maintaining a build rate suitable for cost-effective volume production.

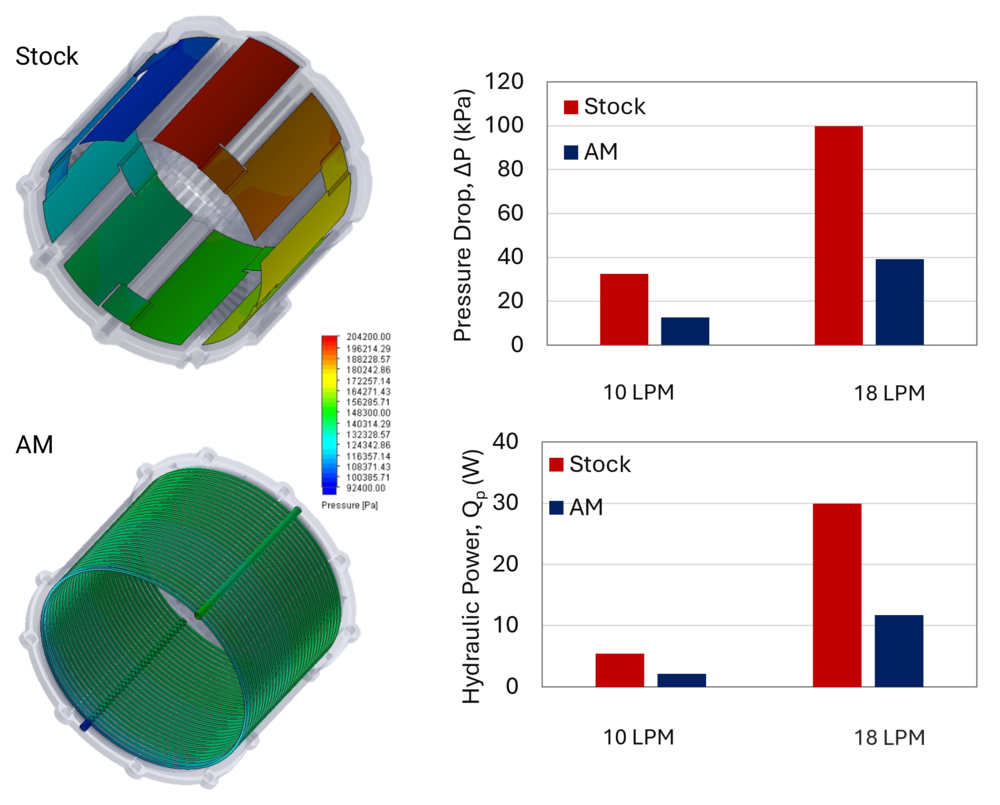

The results: measurable performance improvements

The demonstrator part showed a vastly reduced pressure drop to move the same amount of liquid coolant through the e-motor housing compared to a standard e-motor. More uniform cooling was also observed, due to the vapor chamber heat-spreading effect and more efficient heat transfer:

- >60% reduction in pressure drop and hydraulic power consumption

- 39°C improvement in temperature uniformity across the motor housing

- 18°C reduction in maximum temperature of the motor windings

In the EV sector, thermal management improvements have significant implications for efficiency and performance. By reducing the power needed for cooling, more energy can be reserved for propulsion, extending vehicle range and lifespan of the system. Better temperature uniformity also reduces hot spots that can accelerate component degradation.

The evolution of Additive Manufacturing part design, advanced materials and processing techniques

This project was made possible by combining several advanced technologies:

- Aluminum powder design: Equispheres powder, designed for high-laser powers and layer thicknesses, provided the consistent melting behavior necessary for creating both solid structures and porous wicking surfaces in a single build.

- Advanced laser technology: The AconityTWO printer equipped with dynamic laser control of spot size, power, speed, and scanning patterns allowed precise control over the melt pool dynamics.

- Process innovation: Optimized printing parameters developed by the Equispheres applications engineering team enabled the creation of functional wicking structures integrated seamlessly with solid components.

Industry applications for integrated passive cooling

While this project focused on e-motor cooling, the technology has applications across industries where thermal management is crucial:

- LED lighting systems requiring heat dissipation

- Power inverters and on-board chargers

- Lightweight, efficient components for aerospace and defense

- Passive heat transfer in electronics and semiconductors

- Renewable energy systems

The future of Additive Manufacturing for thermal management

As more heat-producing components are housed in smaller form factors, integrated cooling solutions will be essential. This project demonstrates the application of AM for functional, production-ready parts that expand the design space for innovative products.

By pushing the boundaries of part design with Additive Manufacturing, Martinrea and Equispheres are creating not just new components, but entirely new approaches to solving complex engineering challenges.

Want to stay updated on Equispheres’ latest innovations in additive manufacturing materials and applications? Join our mailing list to receive our quarterly newsletter and technical updates.

About the AMUG Technical Competition

The Additive Manufacturing Users Group (AMUG) Technical Competition showcases innovative applications of additive manufacturing technology. The Advanced Concepts category highlights groundbreaking approaches that push the boundaries of what’s possible with AM.

About the collaborators

Equispheres develops breakthrough technologies for the production and deployment of aluminum powders in Additive Manufacturing (AM). Leveraging our patent-pending technology and process expertise, we strive to eliminate the performance and economic obstacles limiting the full potential of metal AM at industrial scale.

Martinrea International Inc. (TSX: MRE) is a leader in the development and production of quality metal parts, assemblies and modules, fluid management systems, and complex aluminum products focused primarily on the automotive sector.